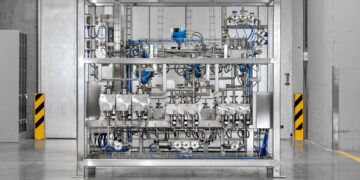

For a reliable process, quality and manufacturing guidelines must be adhered to, even with frequent product changes, and production parameters must be documented. In addition, Bürkert Fluid Control Systems now offers its FLOWave flow meter Type 8098 as an ATEX-certified version up to Ex zone 2 for production processes in potentially explosive environments.

The compact and lightweight device measures the volume flow independently of the conductivity of the medium and is therefore also suitable for measuring ultrapure water and alcohols. This means that it can be used, for example, in the manufacture of pharmaceuticals and spirits as well as in lacquer and paint production. The flow sensor also measures the temperature and the density factor and can, for example, quickly and reliably detect a change in media during rinsing processes. It supports Bürkert’s own EDIP platform (Efficent Device Integration Platform) for easy digital integration into the system control.

Hygienic measurement thanks to SAW technology

The flow meter works according to the SAW method (Surface Acoustic Waves). With this measuring principle with surface acoustic waves, there are no dead spaces or sensor elements in the measuring tube. This means that the CIP / SIP-capable flow meters can be cleaned just as easily as normal pipelines, which lowers operating costs. All parts that come into contact with the medium are made of stainless steel. The sensors thus meet the highest hygiene standards and facilitate the validation of production or cleaning processes.